SHIPPING CONTAINER DELIVERY guidelines

Before purchasing a shipping container, you’ll need to make sure that you have enough space for a smooth roll-off delivery. By reading our delivery guidelines you can better understand the minimum requirements.

WHAT TO AVOID FOR A STRESS-FREE DELIVERY?

Rough Roads

Roads made of dirt, gravel, or with damaged pavement may not be suitable for shipping container delivery due to their road weight limits and the risk of getting stuck, causing damage to the road and equipment, or being environmentally disruptive.

STEEP ROAD INCLINES AND DECLINES

Steep inclines can make it impossible to haul a load uphill, while a steep decline can pose safety hazards to the delivery crew and the surrounding environment. Please get in touch to receive an evaluation of your delivery route and determine if your local roadway grades qualify for a successful shipping container delivery.

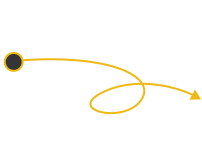

TIGHT TURNS

Shipping containers require sufficient turning clearance to prevent getting stuck, causing damage, and for safety purposes. Delivery of a 20ft shipping container will require a minimum of 60ft straight line clearance, while a 40ft container will require a minimum of 125ft straight line clearance to perform a safe and effective turn. For these reasons, narrow roadways in rural settings surrounded by trees and ditches, as well as roads in urban settings with crowded buildings and parked cars, can make shipping container delivery impractical.

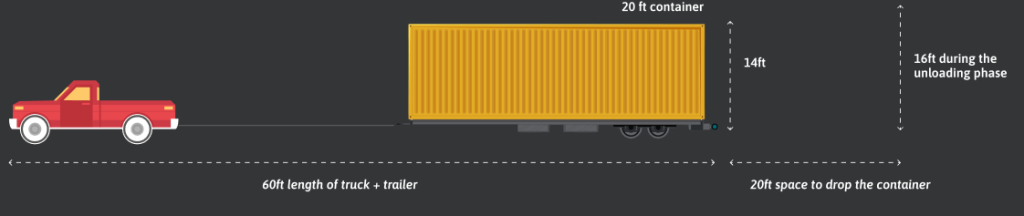

Height Restrictions such as Overhanging Trees, Power Lines, and Low Bridges

Any obstacle that does not offer at least 14ft of vertical clearance is considered a height restriction for shipping container delivery. These may include power lines, trees and tree branches, gateways, arches, building eaves, and low bridges. It’s essential to ensure sufficient vertical clearance along all sections of your local roadways to avoid delivery hazards and delays.

Width Restrictions

Shipping containers require a minimum of 14ft of horizontal clearance to pass through without getting stuck or causing delays.

Narrow roadways less than 14ft in width may not permit a shipping container delivery, and a lack of alternatives may result in cancellation.

Ideally, any roads leading to your location should be a standard 2-lane marked road at minimum.

WEATHER-AFFECTED ROADWAYS

Roads affected by weather can make shipping container delivery impractical and dangerous. These conditions include icy roads, flooded roads, muddy roads, roads covered with debris after extreme weather, and snowy roads which have yet to be plowed.

We’re always happy to work with our customers in planning a shipping container delivery that accommodates their schedule and ensures a safe and hassle-free process for everyone.

Not sure if local roadways will accommodate a successful shipping container delivery to your location? Contact us to receive a free delivery guideline assessment and review of your local roads and features before ordering your shipping container from Used Conex.

TILT BED SHIPPING CONTAINER DELIVERY

Tilt bed trailers are designed to perform secure shipping container delivery with direct placement on the ground at the drop-off location.

- They are ideal for small businesses, private properties, and other locations that do not have specialized forklifts or cranes to haul containers or remove them from the delivery vehicle. With a tilt bed trailer, container delivery planning will include the location, space, and conditions in which the container will be placed. Because it will not be possible to move the container once it is down without equipment, it’s essential to ensure that the surface and location are suitable for a storage container drop-off.

- Used Conex works with you to determine if a tilt bed container delivery suits your needs. Tilt beds can haul 20ft and 40ft shipping containers. Because tilt bed delivery involves pulling the trailer out from underneath the container, this delivery method requires a minimum of 125ft straight line clearance. You will also need to decide which ways the doors will face before delivery, as this will determine how the container is loaded onto the trailer.

FLATBED SHIPPING CONTAINER DELIVERY

Unlike tilt bed trailers, Flatbed trailers do not have their own off-loading feature. This requires any storage container delivered on a flatbed to be off-loaded manually using a crane, forklift, or another heavy lifting method. Flatbed storage container delivery is intended for business locations or properties with dedicated heavy lifting equipment on site. Because you will be responsible for off-loading the shipping container, preparation of drop-off is relatively straightforward compared to tilt bed delivery.

SHIPPING CONTAINER DELIVERY SPACE CLEARANCE

- 80ft-100ft straight shot clearance

- 16ft height clearance

- 12ft width clearance

- 100ft-125ft straight shot clearance

- 16ft height clearance

- 12ft width clearance

Before buying new or used shipping containers, it’s important to ensure the drop-off site is adequately equipped to accommodate a container delivery. This includes having enough space to store a 20ft container or a 40ft container and enough area for delivery vehicles and other equipment to perform their duties safely and securely. You’ll also need to ensure that any limited-access locations have minimum height and width clearance for the truck, trailer, and shipping container before placing your order. Roads leading to your business location or private property will also need to accommodate truck and trailer clearance. They must be suited for heavy vehicles regarding road weight limits, road conditions, road grades, overhanging objects, and turning radiuses.

At Used Conex, we’re here to help you prevent any delays or setbacks in your shipping container goals by being fully prepared ahead of time. From consultation to site inspection, we offer a range of services to help you determine the optimal site and

schedule for your storage container delivery.

Based on the length of the container and the type of delivery trailer, a specific minimum clearance is required.

20ft Shipping Container

- 100ft Straight Line Clearance: This applies to roads leading to the drop site and at the drop site itself. With a 20ft shipping container, our truck and trailer will require at least 80ft straight line clearance to be able to unload the unit.

- 14ft Vertical Clearance on the Road: Roadways leading to the drop-off site should be free of any overhanging obstacles with a minimum of 14ft vertical

clearance at all times. - 12-14ft Width Clearance.

- 16ft Vertical Clearance at Drop-Off Site.

40ft Shipping Container

- 100ft Straight Line Clearance

- 14ft Vertical Clearance on the Road: This includes all sections of the road leading to and at the drop-off location.

- 12-14ft Width Clearance.

- 16ft Vertical Clearance at Drop-Off Site.

SHIPPING CONTAINER DROP SITE PREPARATION

Avoid Difficulties and Delays by Preparing for Shipping Container Delivery with this Simple Checklist.

A big part of the work involved with shipping container drop-offs is being prepared. When your location is well-suited for drop-offs, storage, or transfer of shipping containers, the process can be completed in just 1 hour or less. Having a suitable drop site will also ensure that the container is not damaged or compromised during storage. It also makes its removal much more efficient in the case of future transfers, alternative uses, and resale. Here’s what to consider before ordering a shipping container to help save time and avoid safety risks, equipment damage, or delivery cancellation.

- Short-Term or Long-Term Site Preparation?

Depending on your goals, your site may require short-term or long-term container storage preparation. Long-term storage or permanent use typically requires additional steps to ensure the container is not damaged or compromised over time while being conducive to your goals. Please get in touch for more information on the difference between long-term and short-term site preparation.

- Delivery Vehicle & Trailer Clearance

Drop sites without sufficient clearance can make it difficult or impossible to perform container drop-offs. For successful delivery and future logistics, ensure that your drop site offers enough clearance to maneuver the vehicle, trailer, and shipping container into place. Learn more about shipping container delivery clearance.

- Level Ground

The drop site and surrounding area should be on level ground to ensure secure delivery vehicle access and container placement. It is also necessary to create even weight distribution across all four corners of the shipping container. Land that is not level can make it difficult for delivery vehicles to get into position and lead to container damage due to uneven weight distribution resulting in pinched doors, bent corners, and other defects.

If the ground is not naturally-level, it can be modified with stone pavers, blocks of wood, gravel, or railroad ties under the corners to create even weight distribution.

- Drop Site Ground Surfaces

Shipping containers can be dropped off on any surface that is firm, level, and dry. Drop sites will ideally have an asphalt or concrete space prepared for shipping container drop-off. However, surfaces such as compact dirt, gravel, and even grass may be suitable — provided that they are level, safe from weather, and offer even weight distribution and support. This will ensure that the shipping container does not sink or move when in position. Surfaces such as sand, soft dirt and muddy grounds are not recommended as it may result in container shifting, sinking and damage.

- Drop Site is Free of Debris and Obstacles

Make sure your storage container drop site is free of rocks, tree stumps, branches, or any debris that can cause an inconvenience or equipment damage during your storage container drop off.

- Drop Site is Free of Safety Hazards

Apart from sufficient vertical and horizontal clearance, the drop site should also be free of any safety hazards such as low-hanging wires, cables, branches, and equipment that may pose risks during drop off. In the case of limited visibility, crews can rely on spotters to help them navigate the vehicles and container into position.

- Weather Conditions

From transportation to drop-off, a big part of successful delivery is keeping ground surface conditions in mind. To prevent difficulties and delays, it’s important to plan your shipping container delivery around weather forecasts that may suggest suitable surface conditions. Bad weather may result in snowy or icy roads and surfaces, muddy roadways and grounds, flooding and soft soil that may lead to difficulties and delivery cancellation. We’re here to work with you and determine the quickest, safest and most optimized delivery schedule for your location and needs.

BEING READY

Another important step to not overlook is simply being ready for delivery day. Make sure that your neighbor residents or businesses are informed about your delivery and that no vehicles, equipment, or other obstacles are in the way. You’ll also want to ensure that you or a representative is onsite at the time of arrival to avoid delay fees. Your contact phone number should be available at all times before and during delivery to prevent miscommunication or other complications.

If you are unsure about your shipping container drop site, it may be wise to have a backup drop site just in case. If the delivery crew considers your drop site unsafe or otherwise unsuitable, they may request that your shipping container be dropped off elsewhere. If you insist on an unsuitable drop-off location, you may be asked to sign a waiver for any damage or other setbacks that may be incurred during unloading.

How it happens, we advise you to watch the video below

FAqS

We’ve answered the most common questions about receiving shipping containers from Used Conex. From delivery time to site preparation, you’ll find everything you need to know here.

Delivery is typically included in the total container quote, but the exact cost depends on your location, and container size. We offer transparent, all-in pricing — no hidden fees. You can get an instant quote by entering your ZIP code on any product page.

Most containers are delivered within 7 to 10 business days after order confirmation. Delivery times may vary based on your location and weather conditions. Our team will coordinate a convenient time window and call ahead before arriving.

In most areas, no permanent foundation is required — containers can be placed on compacted dirt, gravel, or concrete pads. Permit requirements vary by city or county. We recommend checking local zoning codes or asking our team if you’re unsure.

Yes — when ordering, you can specify door orientation (facing cab or rear of truck). This ensures your container is positioned correctly when it slides off the delivery trailer.

If the site isn’t accessible or safe, delivery may be rescheduled, however, you need to inform the logistics team ahead of time or you could incur a dry-run fee. Make sure to contact us in advance if anything changes.